Bubble Wrap Manufacturing Process: Complete Guide and Machine Selection Tips

Bubble wrap is one of the world's most iconic and widely used packaging materials, playing a crucial role in protecting goods during storage and transit—especially in e-commerce, electronics, and the shipping of fragile products. This article explores what bubble wrap is, the bubble wrap manufacturing process, customization options, environmental considerations, and the best machines for producing it.

What Exactly Is Bubble Wrap?

Bubble wrap, also commonly referred to as an air bubble sheet in industrial contexts, is a flexible plastic sheeting embedded with air-filled bubbles that provide cushioning and protection for delicate items. It is u fsed across various industries, including electronics, automotive, glassware, and online retail. The bubbles absorb shocks and prevent damage during transportation, making bubble wrap packaging essential for both businesses and individuals who ship goods frequently.

What is Bubble Wrap Made Of?

Most bubble wrap is made from low-density polyethylene (LDPE), a lightweight and flexible plastic. LDPE is chosen for its durability, transparency, and ability to retain air. Depending on the application, manufacturers may incorporate additives such as:

- Anti-static agents to prevent electrostatic discharge for electronics packaging

- Colorants for branding or product identification

- UV inhibitors for outdoor applications

- Biodegradable or recycled polymers for enhanced environmental performance

Bubble Wrap Manufacturing Process

The bubble wrap manufacturing process—sometimes referred to as the air bubble sheet manufacturing process when discussing sheet production—is a fascinating combination of extrusion, vacuum forming, and lamination. Here's a step-by-step breakdown :

Step 1 : Melting and Extrusion

The process begins by melting LDPE resin pellets in an extruder. The molten plastic is then forced through a flat die to form a thin film. This film will become the bubble layer.

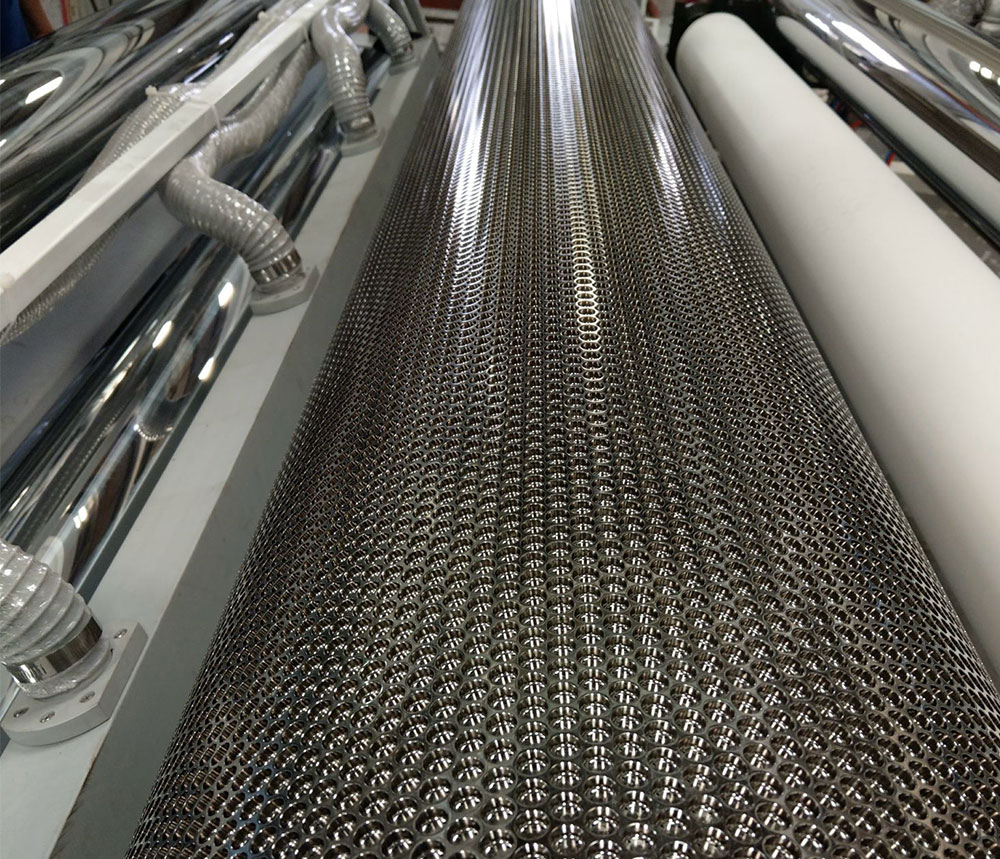

Step 2 : Bubble Formation

The warm plastic film is immediately fed over a large roller with evenly spaced holes. Vacuum pressure pulls the film into these holes, forming the signature bubble shapes. The size of the roller indentations determines the bubble diameter.

Step 3 : Sealing with a Second Film Layer

A second flat plastic film is laminated on top of the bubble layer to seal the bubbles and create the final structure. Precision is critical at this stage to maintain air retention and durability.

Step 4 : Cooling, Cutting, and Rolling

The two-layer film passes through cooling rollers to solidify and stabilize the bubbles. It is then slit into desired widths and wound into rolls for easy storage and shipping. This step also allows customization of roll size.

Understanding the bubble wrap manufacturing process empowers businesses to choose better packaging solutions tailored to their needs.

Customization Options

Bubble wrap isn’t one size fits all. Manufacturers offer various customization options to meet different packaging demands.

Bubble Sizes

- Small bubbles (1/8") : Ideal for delicate and lightweight items

- Medium bubbles (5/16") : Versatile for general packaging

- Large bubbles (1/2") : Best for heavy or fragile items needing extra cushioning

In addition to the common sizes above, any other dimensions you can think of can be customized.

Sheet Dimensions and Perforation

Bubble wrap rolls are available in various widths (typically 48" to 84") and lengths. Perforated rolls allow easy tearing without tools, improving packing efficiency.

Color and Shape Customization

Colored bubble wrap (e.g., pink for anti-static, green for eco-friendly) can enhance branding or product identification. Custom die-cut shapes are also available for specialized packaging needs.

Is Bubble Wrap Eco-Friendly? Environmental Considerations and Solutions

Is Bubble Wrap Recyclable?

Standard bubble wrap is recyclable but typically not through curbside recycling programs. It must be taken to facilities that accept plastic film, such as grocery store drop-offs. Because it is made of LDPE, it falls into the same category as plastic bags.

Eco-Friendly Alternatives

In response to environmental concerns, manufacturers now offer:

- Biodegradable bubble wrap : Breaks down faster under composting conditions

- Recycled content bubble wrap : Made from post-consumer plastic

- Paper bubble wrap : A kraft paper-based alternative for full recyclability

Read more about Chi Chang’s Innovation: Chi Chang's Promise to Customers - Verticalizing Stretching Units Saves 20% Space and Labor Costs

Best Air Bubble Wrap Manufacturing Machines

Choosing the right air bubble wrap making machine is critical to maintaining quality, efficiency, and competitiveness in the bubble wrap manufacturing process. For a deeper dive into different types of equipment and production setups, check out All You Need to Know about Air Bubble Film Making Machines.

Key Features to Look For

- Consistent film thickness and bubble size for product quality

- High-speed operation to meet production demands

- Energy efficiency and low maintenance

- Customizable configurations for different bubble sizes and materials

Types of Bubble Wrap Manufacturing Machines

| Machine |

3 Layer Air Bubble Film Machine

|

3-layer Air Bubble Film Extrusion Line (With 2 Unwinders)

|

10-layer Co-Extrusion Air Bubble Film Extrusion Line

|

|---|---|---|---|

| Max Width | 3,000MM | 3,000MM | 3,000MM |

| Layer Flexibility | 2–10 | 2–10 | Fixed 10 |

| Best For | Large volume, general packaging | Lamination & versatile needs | Premium, high-strength packaging |

| Tech Type | Standard | 3-layer w/ dual unwinders | 10-layer co-extrusion |

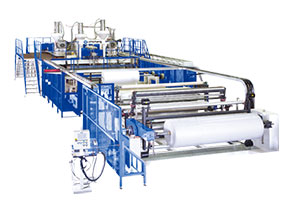

- 3 Layer Air Bubble Film Machine : Ideal for producing extra-wide bubble wrap rolls, perfect for industrial or furniture packaging.

- 3-layer Air Bubble Film Extrusion Line (With 2 Unwinders) : Offers flexibility for adding layers (e.g., printed film, foil, kraft paper), great for customized or value-added products.

- 10-layer Co-Extrusion Air Bubble Film Extrusion Line : Best suited for premium packaging segments like electronics or temperature-sensitive goods due to co-extrusion capability.

Read more about Chi Chang's achievements: Chi Chang's Success Story: Securing a $1.2 Million Order with Outstanding Equipment and Service.

Real-World Success : Chi Chang’s Case Study in Bubble Wrap Production

At Chi Chang, we don't just manufacture equipment—we deliver complete production solutions. One of our recent success stories highlights our collaboration with a leading packaging manufacturer in Southeast Asia to build a state-of-the-art bubble wrap production line.

Project Highlights:

- Objective : Expand bubble wrap production capacity while maintaining high material efficiency.

- Solution : Deployed our 3-layer Air Bubble Film Extrusion Line customized for dual-layer lamination with high-speed output.

-

Outcome :

- Increased production volume by 35%

- Reduced film material waste by 18%

- Achieved faster lead times and improved product quality

This successful implementation not only strengthened our client’s market competitiveness but also demonstrated how Chi Chang’s equipment can be tailored to meet diverse and demanding operational goals.

Interested in learning how Chi Chang can help your business achieve similar success? Get in touch with us here.

See the Bubble Wrap Manufacturing Machines in Action: Explore More on LinkedIn

For those curious about how Chi Chang’s machines perform in real-world settings, we’ve shared a video of our 2700mm-wide, 3-layer air bubble film machine in operation. This model is specifically designed for producing large bubble film and supports fully customizable configurations from 1000mm to 3000mm sheet widths.

Whether you're targeting general protective packaging, anti-static wraps for electronics, or UV-resistant films for greenhouses and pool covers, this system offers the flexibility and reliability you need.

Watch the full video on LinkedIn to see it in action and explore more real-world applications.

Moving Forward with Your Bubble Wrap Manufacturing Process

Bubble wrap, or air bubble sheet, remains a time-tested solution for packaging, protecting, and insulating goods. Understanding the bubble wrap manufacturing process—also applicable to the air bubble sheet manufacturing process—empowers businesses to select the right materials and manufacturing equipment for their operations. The rise of eco-friendly alternatives and advanced bubble wrap making machines is reshaping packaging to be more efficient and sustainable.

Ready to take your packaging process to the next level? Get in touch with Chi Chang today—let's explore how we can build the perfect solution for your business. With the right knowledge and tools, even something as seemingly simple as bubble wrap can become a smart, strategic asset for your growth.